Custom testers

ALM offers custom designs for a variety of products testing such as motors, generators, appliances, automotive and control modules, medical equipment, water faucets and more. From board/module level to final functional tests, ALM offers solutions for the testing industry needs. Our testers are based on fully automated control using computers or PLCs, according to the customer requirements and designed for a production line environment.

Electrical tests

-

Voltage, current, power, power factor.

-

Resistance, continuity, hipot and ground bond.

-

RF signal losses, GPS signal measurements.

-

Buses and interfaces.

-

CAN, LIN, Serial, USB, Ethernet.

-

Wi-Fi, Bluetooth.

-

Specific customer communication protocols.

Functional tests

-

Air/water leak test and Air/gas/water pressure and flow.

-

Vision inspection, luminosity, color detection.

-

Flame detection, magnetic field detection.

-

Dimensional and distances measurement.

-

Product flashing and programming.

Robotics and special product handling

-

Robots and XY-Axis actuators for product handling or specific test process automation, such as physical product parts manipulation, inspection or measurement.

Customer database interfaces

-

Information retrieval such as parts numbers, serial numbers or programming files.

-

Test results and product specific data archiving.

-

SQL, PLC or alternative interface connections available.

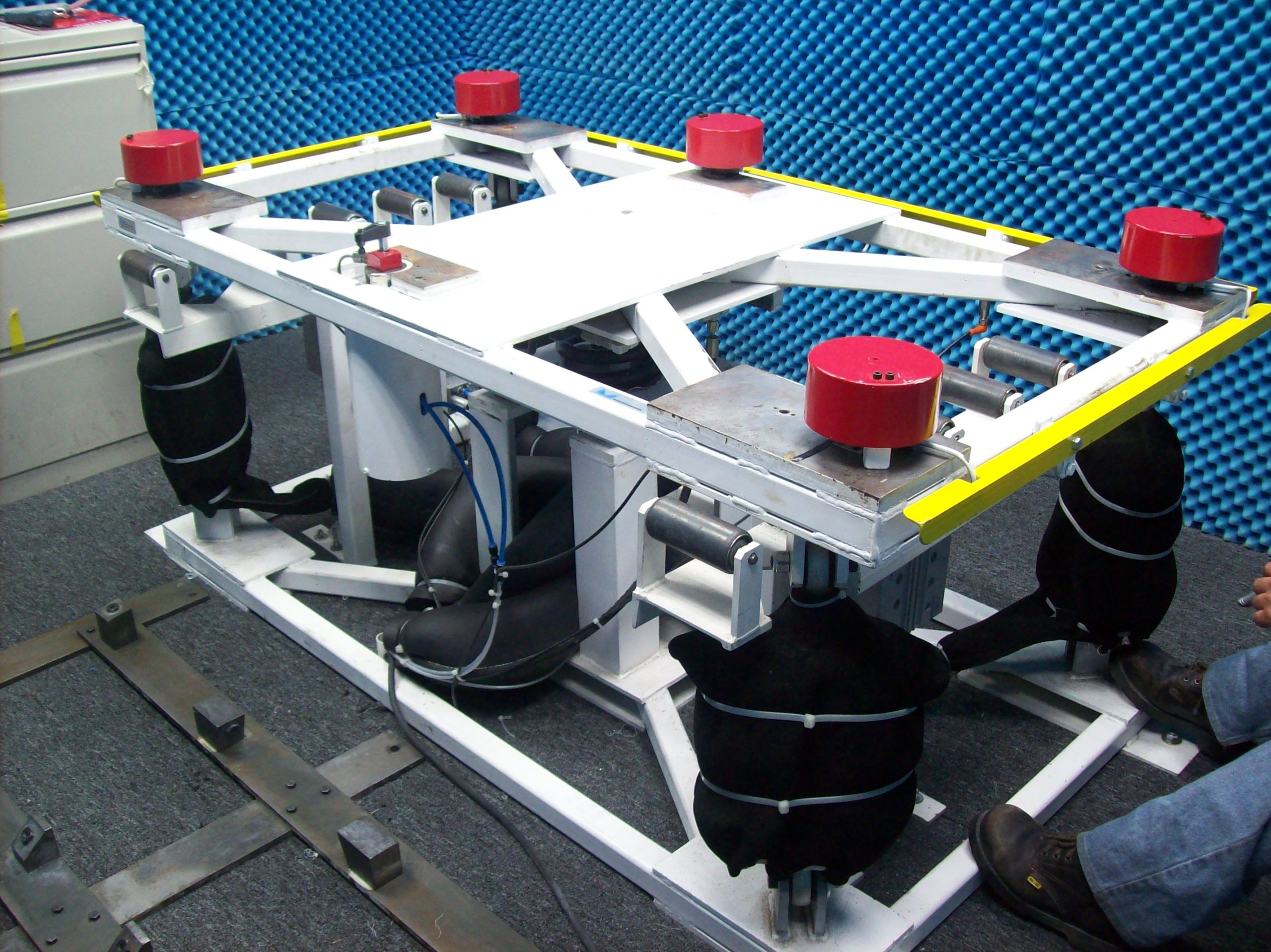

Fixturing

ALM offers a complete range of fixture options, from manual to fully automated systems. Standard fixtures include safety guards and manual mounting and clamping. Custom nests with automatic actuators, pneumatic or electrical for product manipulation are available, as well as multiple test nests.

From board-level pogo pin fixtures, to very high current generator mounting, ALM offers the solution for your product testing needs.

Software

- Windows operating system based.

- Automatic mode for fully automated testing.

- Friendly user interface with visual indication of main measurements and test sequence step status.

- Database for Test Limits and Tests Results.

- Option for ALM 4.0 SCADA interface.

- Specific software requirements are available to integrate, such as interface layout, data to display or test sequence steps display.

Ready to improve your manufacturing process?

Contact us today to learn how our solutions can help you succeed