Robotics

Handling

Robotic handling solutions manage the movement and positioning of materials and components with precision, reducing manual handling and increasing safety and efficiency.

Inspection and Measurement

Robotic inspection and measurement systems provide high-accuracy quality checks and dimensional verifications, ensuring products meet exact specifications.

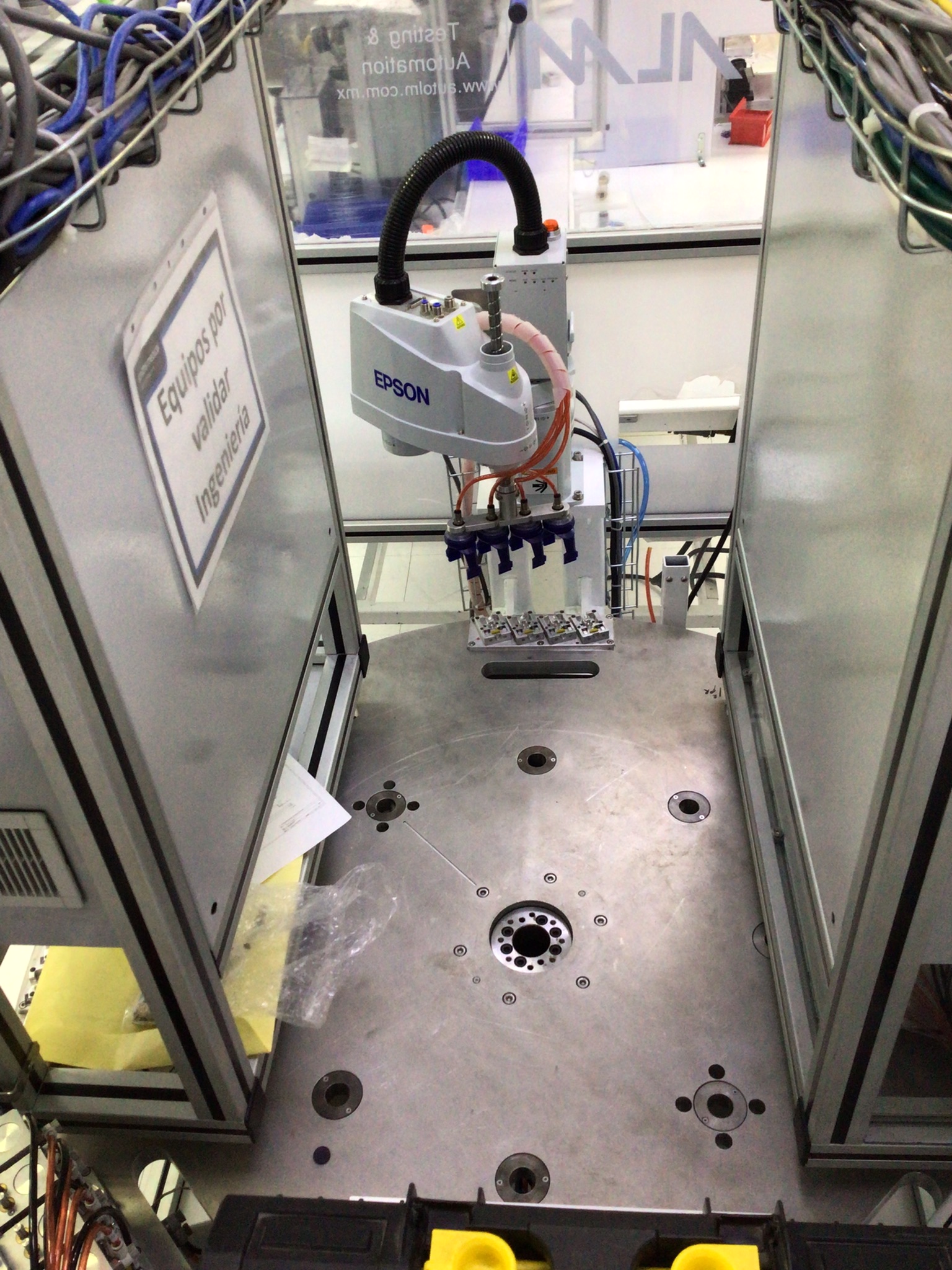

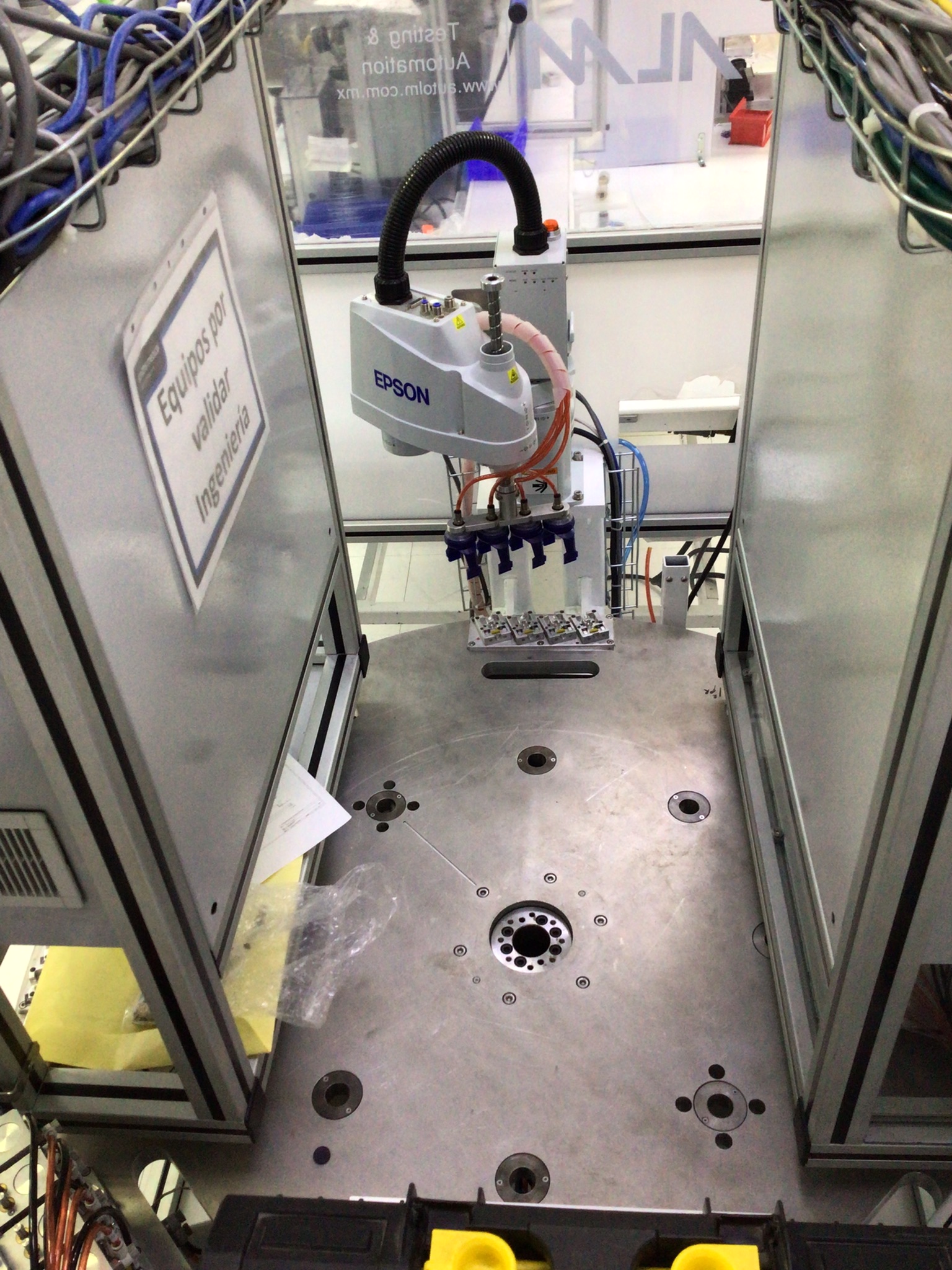

Dispensing Solutions

Automated dispensing robots deliver precise quantities of adhesives, sealants, or other materials, optimizing accuracy and reducing waste in production.

ALM Scope

- Custom design and manufacture tailored to client’s specifications

- Reverse engineering and manufacture of existing equipment

- Upgrades and redesigns for existing equipment

Manufacturing

ALM Manufacturing experience

1 Manipulation

- High-precision handling of components

- Safe handling of components in conditions that would be high-risk for a human operator

- Corrosive chemicals, high temperatures

2 Inspection and measurement

- Dimensional measurement and inspection

- Component presence detection

3 Dispensing

Solutions for dispensing lubricants, adhesives, and other liquid

4 Bin Picking

Component selection, handling and positioning with high precision

5 Automated systems for product and components validation

- Data collection, validation and reporting

- Electrical, hermeticity, vision, dimension tests

6 ALM 4.0 Software development for efficiency, connectivity and data insights

Markets

Applications examples

Automatic assembly lines for appliances

Automatic assembly lines for medical equipment

Contact us

Ready to improve your manufacturing process?

Customer service

Send Enquiry

Contact us today to learn how our solutions can help you succeed