Leak Tester

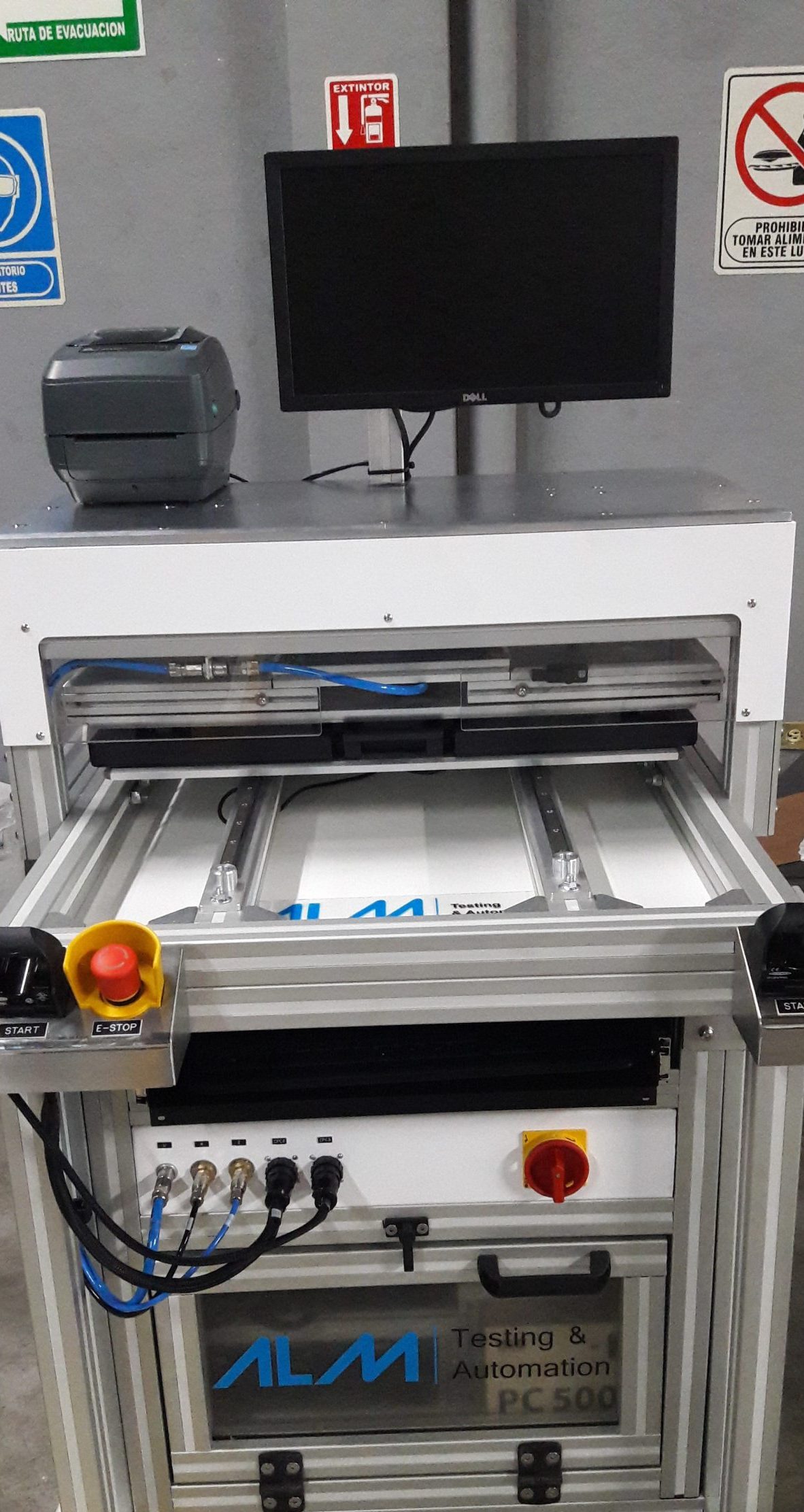

The Leak Tester includes pressure decay or differential pressure tests to find air or water leaks in a product. It is a computer-based, fully automatic equipment designed to test products in a production line environment.

Leak Test

-

Leaking is tested by measuring pressure decay through a specified time interval.

-

Differential leak testing can be used for very low leaks detection, by measuring the pressure difference between a leak-free reference part and the test part.

Flow Test

-

The flow test enables full functionality testing of products that use air, water or gas, such as water faucets, showers, or gas stoves.

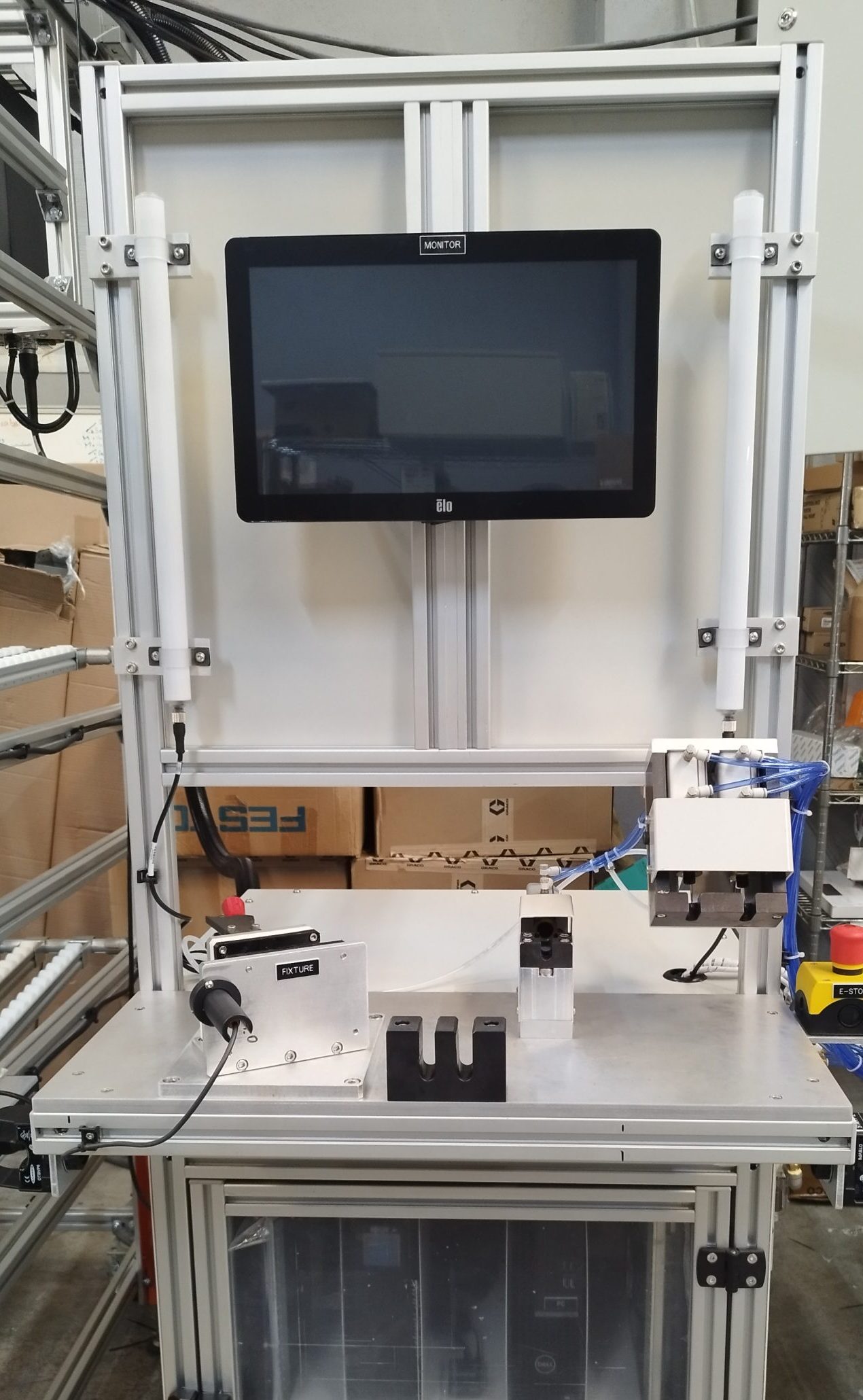

Fixturing

ALM offers a complete range of fixture options, from manual to fully automated systems. Standard fixtures include safety guards and manual mounting and clamping. Custom nest with automatic actuators, pneumatic or electrical for product manipulation such as open/close valves are available. Multiple test nest are also available

Software

- Windows operating system based.

- Automatic mode for fully automated testing.

- Database for Test Limits and Tests Results.

- Option for ALM 4.0 SCADA interface.

Ready to improve your manufacturing process?

Contact us today to learn how our solutions can help you succeed